| Performance | Travel Speed (High/Low) | 3 / 1.6 km/h |

|---|---|---|

| Ground Pressure | 76.1 kPa | |

| Machine Dimension and Weight | Machine Weight | 20,200 kg |

| Overall Length (Folded) | 11,890 (9,410) mm | |

| Overall Width | 2,960 mm | |

| Overall Height | 2,950 mm | |

| Minimum Ground Clearance | 440 mm | |

| Crawler Width | 600 mm | |

| Transport Dimension | Overall Length for Transportation | 9,410 mm |

| Overall Height for Transportation | 2,950 mm | |

| Discharge Conveyor Dimension | Conveyor Length | 4,380 mm ± 250mm |

| Conveyor Width | 800 mm | |

| Conveyor Setting Height | 3,210 mm ± 200mm | |

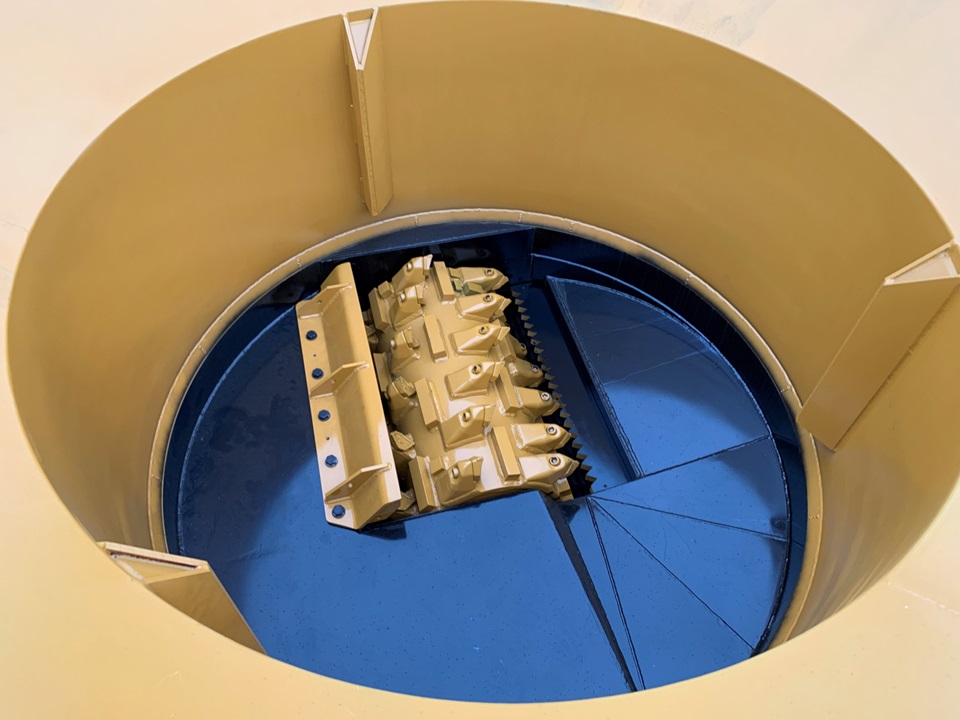

| Tub Dimension | Opening Diameter (Outside/Inside) | 2,900 / 2,600 mm |

| Tub Depth | 1,410 mm ± 50mm | |

| Engine | Name | CAT C18 |

| Nominal Output | 470 kW / 1,900 rpm | |

| Fuel Used | Diesel | |

| Tank Capacity | Fuel Tank Capacity | 470 ℓ |

| Hydraulic Oil Tank Capacity | 270 ℓ | |

| DEF Tank Capacity | 47.2 ℓ | |

| Off-Road Law Emission Regulation Notification and Standards | Name and Model of The non-road special motor vehicle | MOROOKA MC-6000-VIA |

| Name and Type of Specified prime mover | Caterpillar YDS-C18A | |

| Emission Standard | Tier 4 Final / EU Stage V |

| Performance | Travel Speed (High/Low) | 1.9 / 1 mph |

|---|---|---|

| Ground Pressure | 11 psi | |

| Machine Dimension and Weight | Machine Weight | 44,533 lbs |

| Overall Length (Folded) | 39′ (30’10”) | |

| Overall Width | 9’9″ | |

| Overall Height | 9’8″ | |

| Minimum Ground Clearance | 17″ | |

| Crawler Width | 24″ | |

| Transport Dimension | Overall Length for Transportation | 30’10” |

| Overall Height for Transportation | 9’8″ | |

| Discharge Conveyor Dimension | Conveyor Length | 14’4″± 10″ |

| Conveyor Width | 31″ | |

| Conveyor Setting Height | 10’6″± 8″ | |

| Tub Dimension | Opening Diameter (Outside/Inside) | 9’6″ / 8’6″ |

| Tub Depth | 4’7″± 2″ | |

| Engine | Name | CAT C18 |

| Nominal Output | 639 HP / 1,900 rpm | |

| Fuel Used | Diesel | |

| Tank Capacity | Fuel Tank Capacity | 124.2 gal (US) |

| Hydraulic Oil Tank Capacity | 71.3 gal (US) | |

| DEF Tank Capacity | 12.5 gal (US) | |

| Off-Road Law Emission Regulation Notification and Standards | Name and Model of The non-road special motor vehicle | MOROOKA MC-6000-VIA |

| Name and Type of Specified prime mover | Caterpillar YDS-C18A | |

| Emission Standard | Tier 4 Final / EU Stage V |

Downloads SPEC SHEET DOWNLOAD

Feature

Tough undercarriage & Compact design

Thick, seamless rubber tracks provide outstanding durability! The rubber crawler is driven by The HST (Hydro Static Transmission) system. Hydraulic drive transmission provides smooth movement.

MC-6000 is self-propelled, so it can drive directly into the jobsite with its fold-able discharge conveyor.

MC-6000 is self-propelled, so it can drive directly into the jobsite with its fold-able discharge conveyor.

Tub type can crush large amount of woods, branches and leaves

Tub type can crush lumbers with inequality thickness, broadleaf trees that trunk is not straight, thick trunks near by roots and a lot of wood, branches and leaves.

Automatic reverse system

If the cutter drive pressure or cutter rotation speed drop rate falls below the set value during crushing, the feed roller and feed conveyor automatically reverse to prevent material clogging. With this function, materials can be crushed smoothly.

Magnetic separator

You can perform crushing operations with peace of mind, as it effectively removes nails and other materials that may be mixed in with construction waste, ensuring their safe disposal.

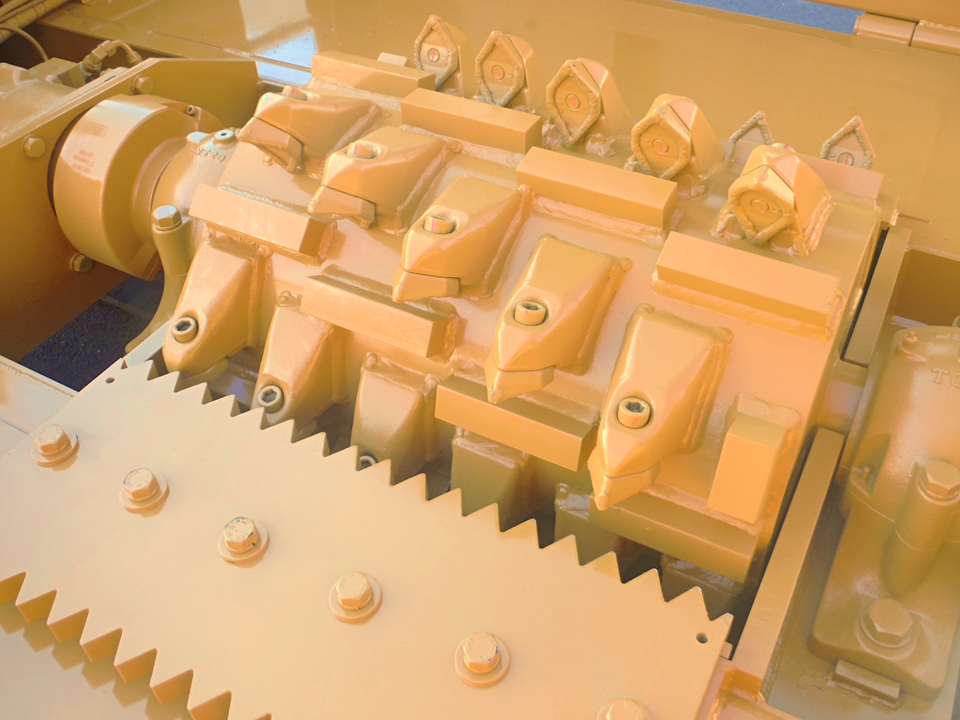

Choice of crushing blade and screen size

Crushing blades and screens can be selected from several types according to the size and shape of the material to be produced.

Maintenance

Improvement in maintainability

Each equipment is installed to perform service and maintenance efficiently. Its structure makes it easy to perform service and maintenance smoothly.

The feed hopper table can be opened and closed at a 90° angle, allowing for maintenance tasks such as screen or cutter blade replacement and cleaning.

The feed hopper table can be opened and closed at a 90° angle, allowing for maintenance tasks such as screen or cutter blade replacement and cleaning.

Reduction of running cost

The cutter blades and counter blades can be reused repeatedly by interchanging their positions, even if they become worn out. This contributes to cost reduction.

< The cutter blade > It can be used twice by turning upside down.

< The counter blade > It can be used four times by turning upside down and front side back.

< The cutter blade > It can be used twice by turning upside down.

< The counter blade > It can be used four times by turning upside down and front side back.

Safety

Emergency stop switch

3 emergency stop switches are installed on both side faces of the product body and operation console.

LED Headlight

The LED headlight is installed in front of the machine, so working at night and in a dark place is safer.

Remote control

Equipped with a remote control for crushing operation. Operations such as starting and stopping material feed and stopping the engine in an emergency can be performed from the operator’s cab of the hydraulic excavator that feeds materials, reducing the user’s burden.

Ecology